PITTSBURGH — The Phipps Conservatory in Pennsylvania is on the verge of completing its new Center for Sustainable Landscapes, a project the organization’s leaders hope will earn recognition as the nation’s largest Living Building Challenge (LBC) project.

PITTSBURGH — The Phipps Conservatory in Pennsylvania is on the verge of completing its new Center for Sustainable Landscapes, a project the organization’s leaders hope will earn recognition as the nation’s largest Living Building Challenge (LBC) project.

The LBC is a certification program organized by the International Living Future Institute, which strives to encourage organizations to embrace green and sustainable building principles. The project’s aim is to become the first structure in the U.S. to attain LBC status, receive a LEED Platinum certification from the U.S. Green Building Council, and be recognized by the Sustainable Sites Initiative, which has a similar aim to the other two award systems, but focuses more on sustainable land management, rather than structures themselves.

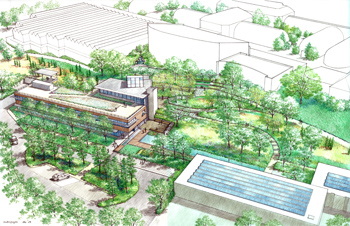

The $23.5 million expansion project will update a 119-year-old non-profit conservatory, creating a state of the art 23,350-square-foot structure. The project was designed by local firm, Design Alliance Architects, with Turner Construction, also out of Pittsburgh, serving as the general contractor.

The design team used a large variety of green techniques in its quest for net-zero energy including: a green roof, energy recovery, geothermal power, natural ventilation, solar photovoltaic energy and vertical axis wind turbines, to name a few.

The project is targeted for net-zero energy consumption, meaning all power needs will be provided by green renewable sources and/or covered by carbon offsets. One of the centerpieces of the net-zero strategy is the heating, ventilation, and air conditioning (HVAC) system, which was created through a collaboration between more than 10 different HVAC companies, who donated equipment. A full accounting of the companies that worked on the project can be found by visiting www.phipps.conservatory.org/project-green-heart/ and clicking on “Center for Sustainable Landscapes.”

“The design uses sustainable equipment and concepts readily-available today, but what’s unique is the unprecedented combination of all this equipment into a net-zero energy application," said Alan Traugott, principal at CJL Engineering, one of the companies that worked on the HVAC system.

Kenneth L. Eirmann, principal at Sensible Equipment, another company involved with the HVAC, said the goal of net-zero energy use seemed impossible at first, but the collaborative process ended up being extremely satisfying.

“Once everybody started conceiving the sustainable possibilities within their own custom manufacturing capabilities, it was an exciting and viable challenge,” he explained.